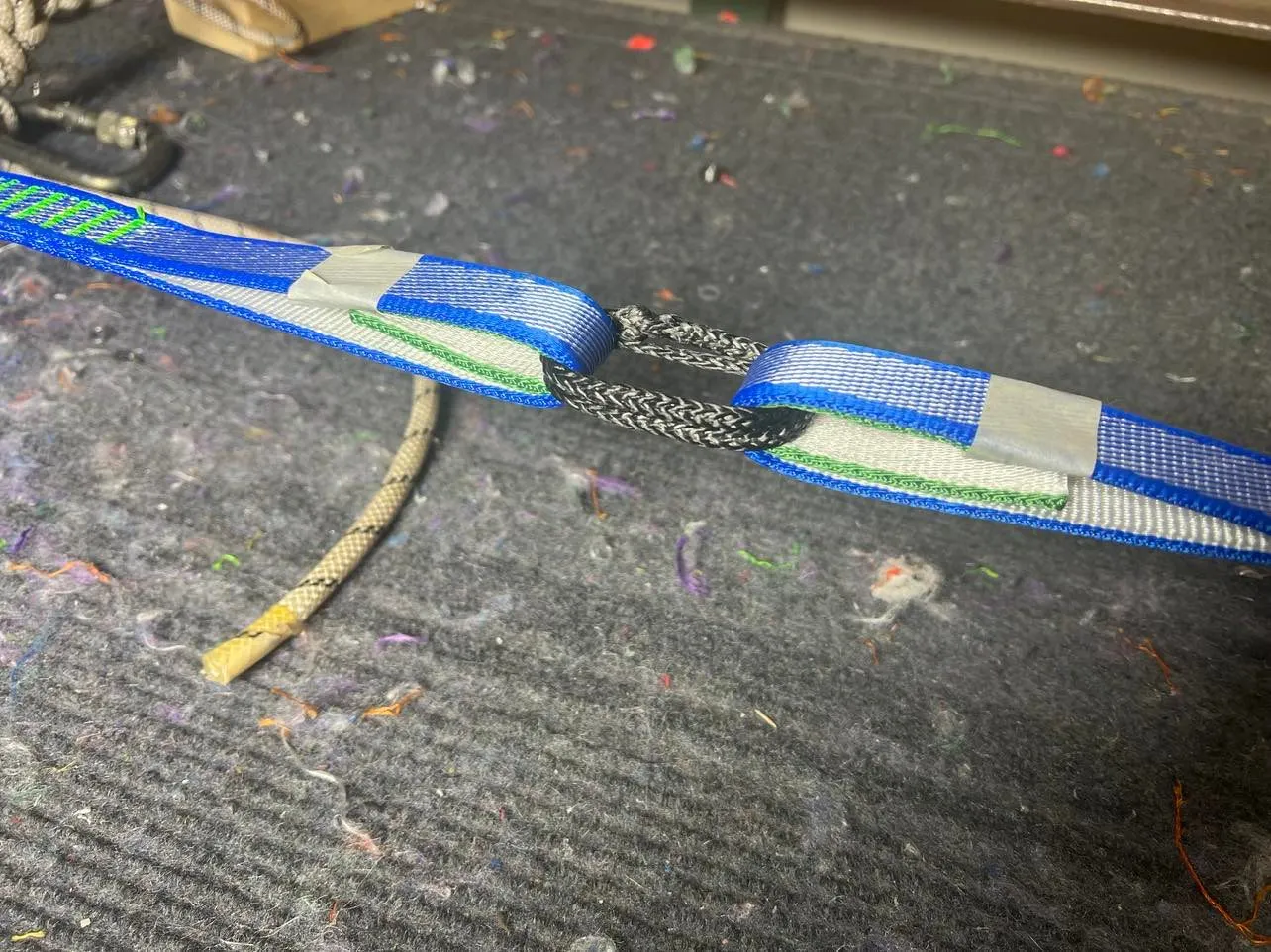

Double Wrapped Grog Splices

A double wrapped 5mm grog connection made and photographed by Clayton Underwood. Double wrapped grogs are a very strong connector. The pictured connector is as strong as, smaller than, and half the weight of a 5mm soft shackle connection. Note: the tail bury on the right side of the picture should start closer to the brummel splice.

Double wrapping grogs was the first major change to using the infinite loops in highline splits. As far as I know, Jerry Miszewski was the first to rig a line on double wrapped 5mm grogs. It was a natural development, as the highliners interested in light and small connections were already double wrapping 4mm soft shackles to reduce the size of the button knots. It also allowed for a smaller gap between sewn loops, since the grogs have a minimum length that was not short enough for some people's taste. The doubled grogs were good enough that almost every split line at GGBY 2022 were rigged on two double wrapped 5mm grogs in a "2 through 4" style system.

This articles goes over the advantages and disadvantages of double wrapped grogs, tips for splicing them, and the breaking strength of 4mm and 5mm double wrapped grogs. There are also some additional breaktests covering questions that were brought up by the original post about grogs.

Update: Usage

In general, one double wrapped grog should replace one connector: a single wrapped grog, a soft shackle, a double wrapped soft shackle, or a quicklink. In a "2 through 4" system that means two double wrapped grogs through all four sewn loops. But in different split designs, for example y2k splits, it means one double wrapped grog through both main loops, and a separate double wrapped grog through the backup loops and sewn connections to the main.

The original version of this article was apparently often read to be implying one double wrapped grog could substitute two single wrapped grogs, and thus that double wrapped grogs do not need to be redundant. This was not intended and is not my recommendation. The examples from real rigs in this post are all two double wrapped 5mm grogs, and the split system I am recommending is a "2 through 4" system with two double wrapped 4mm grogs.

There is no replacement for redundancy, especially in the main load path of a highline.

Benefits of double wrapping

There are a few benefits of double wrapping grogs:

- Strength Double wrapping a connector makes it twice as strong. This makes grogs stronger than almost any webbing, and stronger than a comparable soft shackle (while still being half as light).

- Connection length Some people value a very short connection, and try to get their sewn loops as close as possible. Double wrapped grogs allow you to have sewn loops that almost touch. This also avoids the potential of getting a finger or toe caught in the gap that single wrapped grogs leave.

- Ability to use smaller diameter dyneema Because double wrapping doubles the strength of the grog, it makes double wrapped 4mm grogs a viable alternative to 5mm grogs (see breaktesting below). This reduces weight and counteracts the additional bulk of the double wrap.

Another view of Clayton's double wrapped 5mm grogs under tension.

Downsides of double wrapping

There are a few downsides to double wrapping grogs, although if you're not splicing them onsite, the downsides are quite minimal.

- Harder to splice Double wrapped grogs are harder to splice in the sense that it takes longer and requires more dexterity. The brummel is the same, but because the grog is tighter to the sewn loops, making the bury is more difficult. There are tips below on how to make splicing double wrapped grogs easier.

- Bulkier The same thing that makes double wrapped grogs stronger and brings the loops close together, also adds bulk to the split. There are twice as many strands fitting in the same cross section, so they take up more room. But, a double wrapped grog is still the same size as a soft shackle of the same diameter, without the button knot. Using 4mm double wrapped grogs also helps mitigate this, and is still an extremely sleek connection.

- Increased linear density Double wrapping grogs does not increase the total weight of your split compared to single wrapping them. But it does increase the density of your split by halving the distance that its weight is spread over. This can make the line harder to walk, as there is a more pronounced weight difference compared to the rest of the line. However, the weight density is still less than a soft shackle, and the total weight of doubled wrapped 4mm grogs is lighter than any other connector.

Another view of Clayton's 5mm double wrapped grogs under tension, showing how small the connection size is.

Tips on making double wrapped grogs

At first thought, doubled wrapped grogs seem very hard to make. They are too tight of a loop to pass a normal fid through, so how do you bury the tails? In reality, they're not much harder than a normal grog if you know the method, so follow the tips below to make splicing your double wrapped grogs easier.

- Use a longer piece of amsteel For double wrapped grogs, use a 23" piece of amsteel instead of a 20" piece. The bury lengths should still be 4", but the extra space allows the sewn loops to just fit in place.

- Bunch all of the loops together Once the dyneema is threaded through all of the loops, bunch them together on side to give yourself room to work.

- Pull the ends tight before making the brummel Pull both ends of the dyneema so that the middle loop of amsteel is tight against the sewn loops. This gives you as much of the tails to work with as possible.

- Bury the tails in sections Even with the above tips, there is not enough space to have a straight length of amsteel long enough to bury all of the tails. By burying each tail in two or three short passes of the fid, you can have a very tight connection.

Also, be sure to add webbing thimbles when using soft connectors on sewn loops. The small loop size of double wrapped grogs makes this even more important.

Breaktests

Disclaimer: the breaktests were performed at the Balance Community workshop using their breaktest machine, and with the assistance of Balance Community founder Jerry Miszewski. See the full breaktests at the complete breaktest page (some additional testing data is also included there). All tests were performed on Amsteel Blue unless otherwise stated, and with 4" buries unless otherwise stated.

A 5mm double wrapped grog connection that was rigged at GGBY, Showing the sewn loops touching each other in the split.

4mm Grogs

| Number of Samples | Mean Breaking Strength (kN) | Minimum Tested Value (kN) |

|---|---|---|

| 4 | 22.95 | 20.3 |

Double Wrapped Grogs

4mm Double Wrapped Grogs

| Number of Samples | Mean Breaking Strength (kN) | Minimum Tested Value (kN) |

|---|---|---|

| 3 | 45.4 | 43.8 |

5mm Double Wrapped Grogs

| Number of Samples | Mean Breaking Strength (kN) | Minimum Tested Value (kN) |

|---|---|---|

| 4 | 57.0 | 54.2 |

Additional Breaktests

In addition to testing double wrapped grogs, I tested a few more things that were brought up in response to my original grog post.

"In the hole" grogs

In my original instructions on making grogs, I stated: "Bury each tail back in the same direction as it comes out of the brummel, beginning the bury as close to the brummel as possible". On one side of the grog, there is a clear hole visible where the dyneema is spliced through, and I recommend splicing directly into the clear hole. On the other side, no clear hole is visible, so I recommend splicing at the pick ("V" in the dyneema braid) closest to the brummel.

I was told that some people pull the brummel back all the way until they expose the hole in the other side of the brummel, and splice through there. Thus, both tails are spliced directly into a hole made by the brummel, rather than one side entering the weave from the side. I tested 3 grogs made like this, and saw no strength benefits to intentionally going through both holes. The benefit is a reproducible method, but my recommended method of choosing the closest pick to the brummel that's clearly visible has shown to be reproducible with respect to strength.

| Number of Samples | Mean Breaking Strength (kN) | Minimum Tested Value (kN) |

|---|---|---|

| 3 | 29.41 | 27.8 |

Endura Grogs

One concern when I published my original post on blog was that the strength of a grog with a given bury length would vary significantly with different types of UHMWPE. I was able to test 3 grogs made of New England Ropes Endura 12, which is a variant of SK-75 with a special marine coating. It has a noticeably different feel in hand that Amsteel Blue, which is SK-78 and has a proprietary Samthane coating. The Endura 12 grogs had two very high results, and one that is near the lower end of standard Amsteel grogs. There seems to be no downside in using Endura 12 instead of Amsteel Blue.

| Number of Samples | Mean Breaking Strength (kN) | Minimum Tested Value (kN) |

|---|---|---|

| 3 | 35.7 | 28.6 |

Conclusion

While grogs were already the smallest and lightest connection, double wrapping them can lead to an even smaller and lighter connection. Double wrapped 4mm grogs are extremely light, and take up very little space. I have not had a chance to walk on them yet, but given how good double wrapped 5mm grogs feel, I'm sure they making walking past splits even nicer. And at over 40 kN strong, they are stronger than most webbings.

A 3(!)mm double wrapped grog on a single sewn loop to sewn loop connection, with soft thimbles. Made of D12 MAX 99 by Marlow ropes, it breaks at about 38 kN and weighs 1/3 of an Amsteel Blue 4mm grog. A standard 3mm Amsteel Blue grog will not be this strong.

Grog Links

Below is a list of the other articles I've made regarding grogs, that I will try to keep updated as I go.

- Grog Introduction

- Full information on breaktesting the grogs

- Video of field splicing grogs, with written info guide

Edits

- Made clarifications based on reactions to the post, including the update section on usage (5/27/2023)

Disclaimer

While I have done significant testing of grog splices, and have used them on numerous high traffic rigs to test them personally, I cannot guarantee the grogs you may use on your line, especially if only instructed from the internet. Use grogs at your own risk, and only if you feel comfortable with the information presented here.